Introductions to spring energized seals:

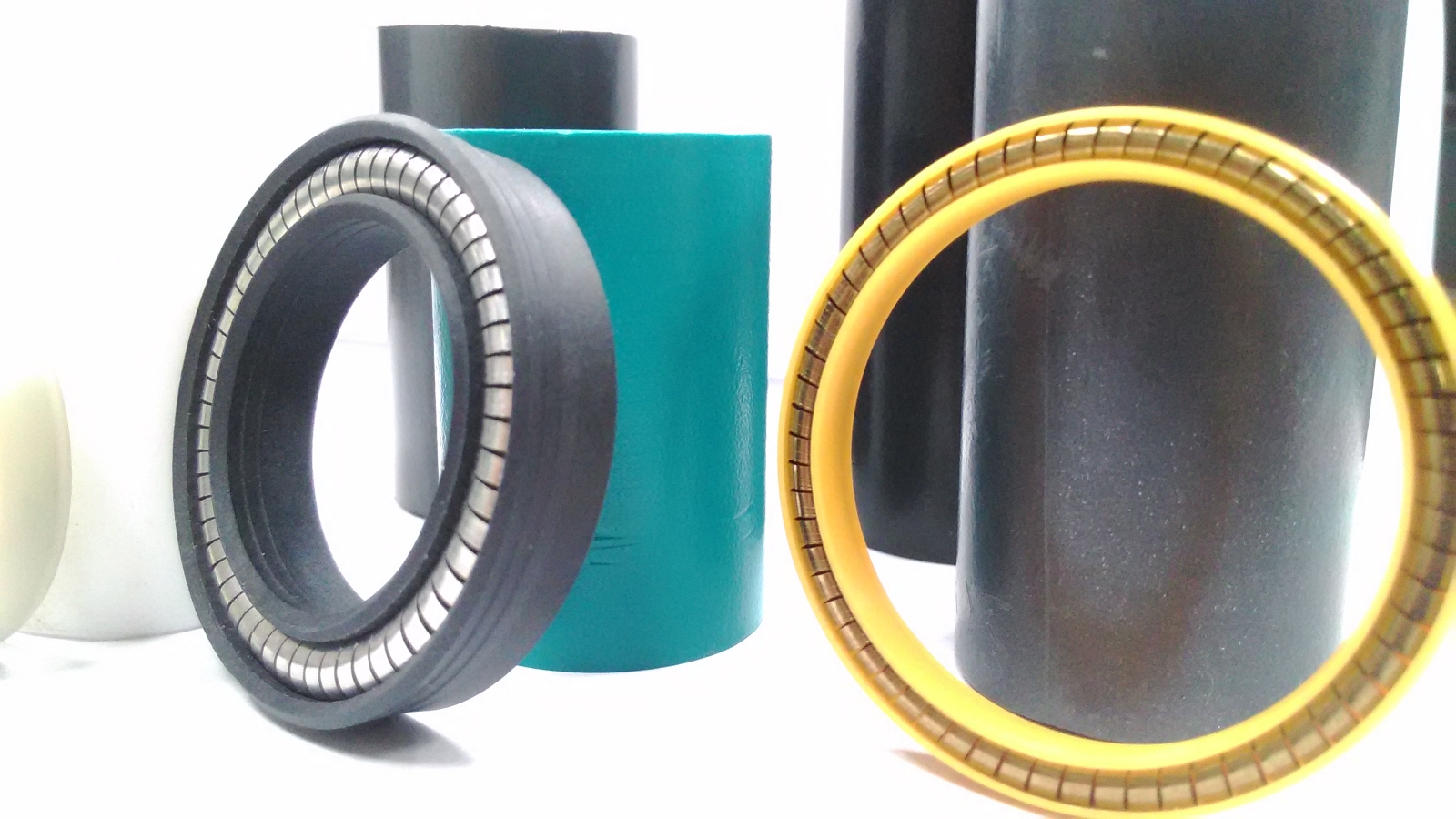

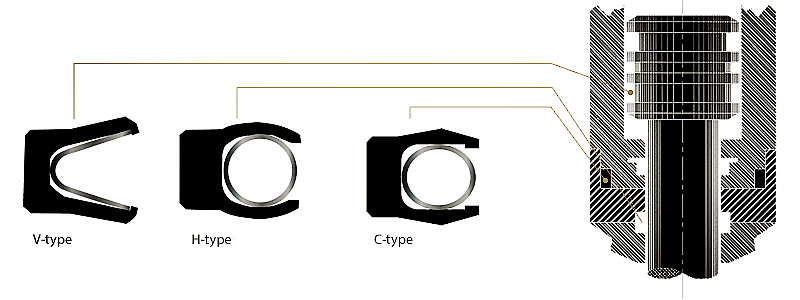

siyoseal®'s spring energized seals is an U-shape spring energized seals function with single acting sealing element. The spring which energizes the PTFE jacket actuates the sealing legs(lips) of the seal. The system pressure assists the spring in creating a leak tight seal between the sealing lips and the mating metal parts. The springs assist in slight misalignment, jacket wear, and maintaining a consistent sealing pressure against the desired target.

siyoseal® has been designed specially to overcome the problems associated with PTFE composite or other high performance plastics like UHMW-PE and elastomer. They are suitable for static, rotary, and reciprocating application in temperatures from cryogenic to 300 ℃, pressure from vacuum to 1400kg/cm2, and speed up to 20m/s, to survive the most corrosive environment.

Three different types of spring energizer are made from corrosion resistant metal alloys such as stainless steel, Elgiloy and Hastelloy to meet most serious corrosive and high temperature application.

Standard siyoseal®are precisely machined to fit AS 568A glands in radial rod, piston and axial face-seal configurations. siyoseal® can replace most of O-ring used in mechanical seal and extend total sealing performance and service life in very aggressive chemical, petrochemical process.

siyoseal® are used in dynamic and static applications where elastomer seals cannot meet the extreme operating conditions of harsh environment. Furthermore, siyoseal® can be a very effective alternative solution to replace any V or U packing set applied in hydraulic components where low friction, high lateral load, corrosive or steam environment are required.

siyoseal always does his best to introduce the most innovative and cost-effective sealing solutions to local customers to help them conquer every difficult sealing problem. Thanks to latest seal-making CNC machine and well-proved worldwide material resource, Siyoseal can produce a spring energized seal specifically meeting your requirements very quickly. This would be the best way for our commitment “To provide excellent sealing performance with extended service life by our sincere effort” to all our customers.

Main Applications:

siyoseal® is designed for thermal and/or corrosive extremes that make the requirement for a stable seal leg unobtainable using other designs or material. It demonstrates excellent capability to the control of friction loads and compensation of manufacturing tolerances or higher side load effects.

●Some typical applications that are ideal for Siyoseal are described as followings.

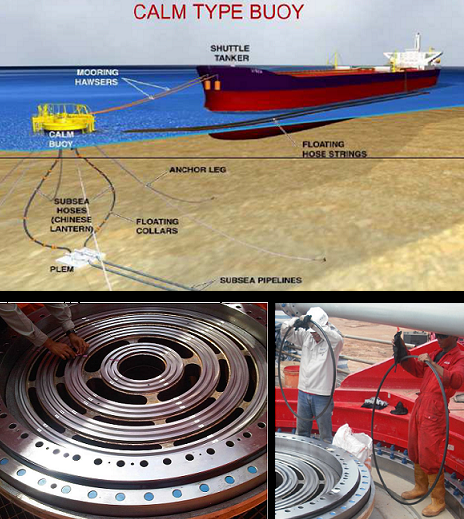

●As face seals for swivel joints in loading or unloading arm equipment

●As needle seals for the paint valves in painting equipment

●As shaft and static seals in vacuum pumps

●As seals for the filling valves of beverage or beer bottling plants and other foodstuffs industry

●As better alternatives in hydraulic components, e.g. high pressure cylinders, low friction cylinders, steering units, and shock absorbers

●In chemical plant equipment and construction

●In the automobile and aerospace industries

●In metering units

●In process equipment and vessel construction

●High wear resulted from high lateral load or poor concentric running condition

Advantages of siyoseal®:

●Excellent dry running capability and high sealing efficiency after a short running-in period

●Reduced wear and friction due to better sealing material characteristics

●Versatile sealing pressure through various spring and seal profile design

●Excellent chemical and thermal resistance

●No volumetric change caused by swelling or shrinkage, good dimensional stability

●Compact seal, well fit in standard O-ring grooves in accordance with AS 568A

●Very long shelf life

●Sterilize in autoclaves or with any possible agen --except radioactive radiation

●Prevent any contamination from the seal

●No stick-slip effect even at very low speed

●Very low friction

●Very small start-up or breakaway force especially for prolonged period out of operation or intermediate operation

Mobile:+86-13715124957

Email: [email protected]

Whatsapp: +86-13715124957