O-ring compression

In order for the O-ring to play a sealing role, the initial compression rate of the groove is very critical. Behave as:

●Obtain initial sealing ability

●Compensation of machining tolerances

●Guarantee a certain amount of friction

●Compensating the permanent compression deformation rate of the material

●Compensate for wear

General compression design: dynamic seal 10%~20%; static seal 18%~25%

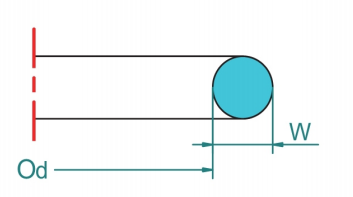

Stretching rate of O-ring

1)Choose the right size

The cross-sectional size W of the O-ring is appropriately selected according to the ratio of the inner diameter ID. For static sealing, the value of W can be selected to be smaller。

2)Inner diameter extension rate (outer diameter compression rate)

For external seals, the O-ring should be stretched when installed in the groove, but the inner diameter stretch rate is between 1% and 5%

For internal seals, the O-ring is installed in the groove and the outer diameter is in a compressed state, but the compression rate of the outer diameter is between 1% and 3%

If the above ratio is exceeded, it will cause an unallowable increase or decrease in the cross-sectional size of the O-ring. The basic rule is that the inner diameter increases by 1%, and the cross-section directly decreases by about 0.5%.

The O-ring material must be selected according to temperature, pressure and medium. In order to adapt the O-ring as a sealing element to a specific application, the mutual restriction of all working parameters must be considered. When determining the application specification, it must be considered To peak temperature, continuous working temperature and operating cycle. Rotating applications must also consider the temperature rise caused by friction.

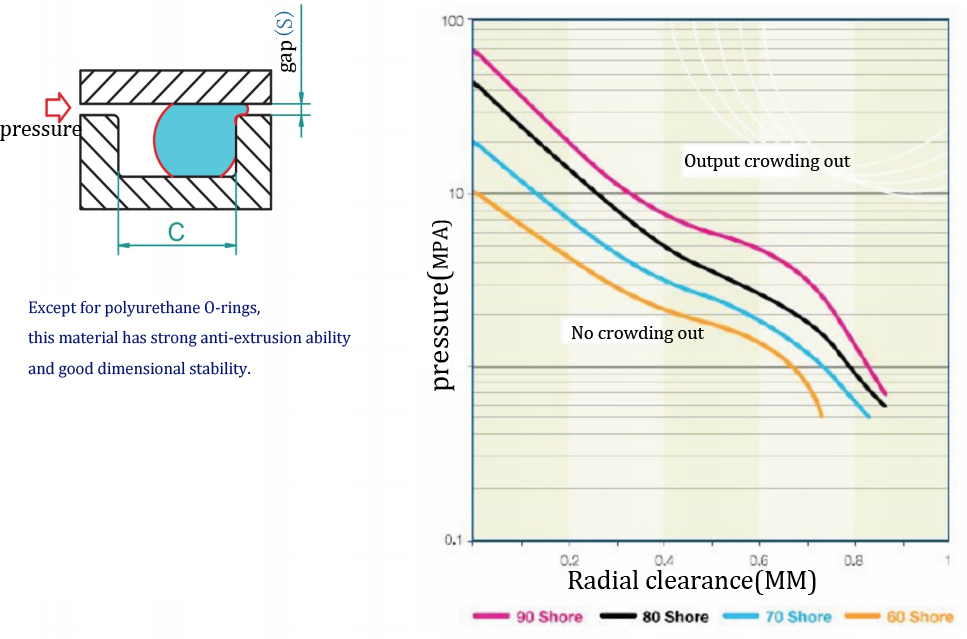

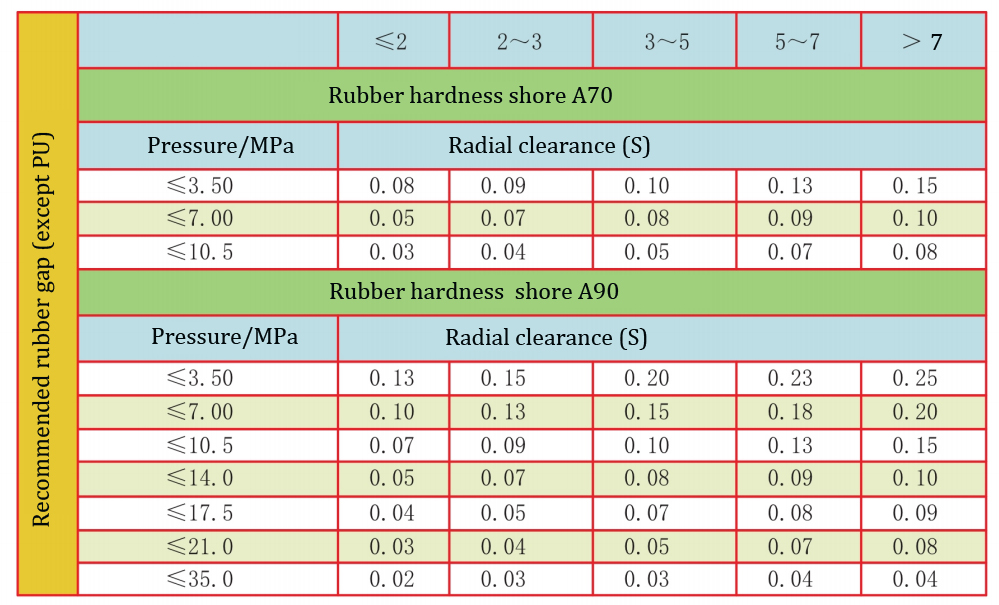

The influence of O-ring installation clearance

Under higher pressure and larger matching clearance, the O-ring is easy to expand to the clearance and squeeze out. In order to eliminate the influence of pressure and clearance of the O-ring, a retaining ring can be added to prevent extrusion

O型圈的沟槽尺寸

The above groove size is for reference only, the groove size should be designed according to the specific working conditions and applications

| Static sealing | Dynamic sealing | ||||

| Groove surface | pressure | Surface roughness/um Bearing area tp>50% | Surface roughness/um Bearing area tp>50% | ||

| Ra | Rmax | Ra | Rmax | ||

| Contact surfaces | No pulsation pressure | 1.6 | 6.3 | 0.4 | 1.6 |

| pulsation pressure | 0.8 | 3.2 | 0.4 | 1.6 | |

Groove bottom and side | No pulsation pressure | 3.2 | 12.5 | 1.6 | 6.3 |

| pulsation pressure | 1.6 | 6.3 | 1.6 | 6.3 | |

Note: After the rubber seal is installed and compressed, its surface shape will become irregular. Therefore, for gas or tight connections, the quality of the sealing groove surface must meet its minimum requirements. For example, scratches, pits, concentric or spiral processing marks are not allowed. For dynamic seals, the matching surface quality requirements are higher.

O-ring installation

Installation points:

●Introduction of 15~20° installation chamfer

●Remove burrs, sharp corners are rounded

●Clean up processing residues (debris, contaminants, etc.)

●Lubricate the seals with lubricating grease (the chemical compatibility of the two materials needs to be considered), and lubricants containing solid additives cannot be used

●Do not use sharp tools for installation, try to use auxiliary tools

●Do not stretch the O-ring excessively

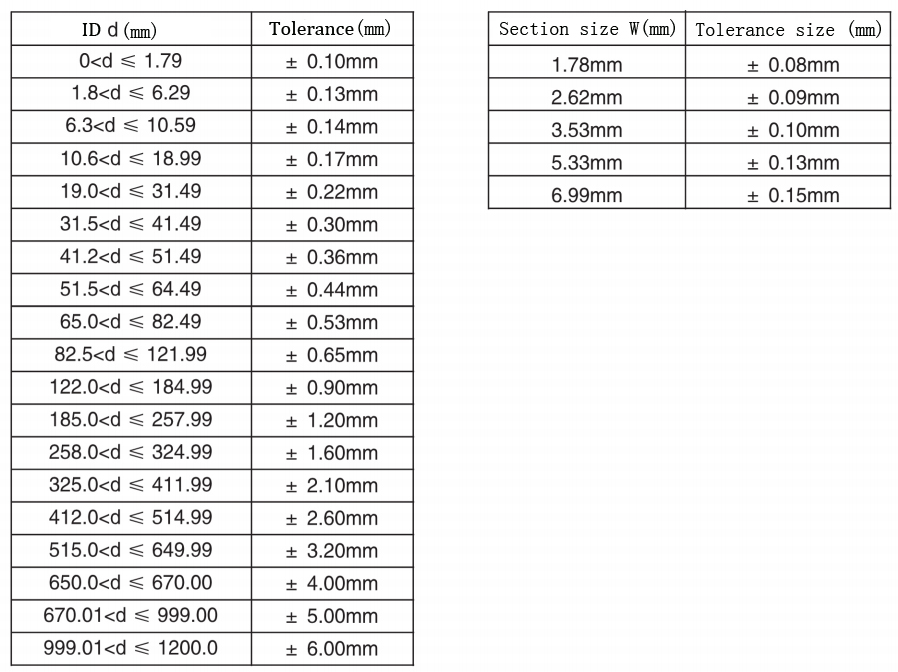

Dimensional tolerance of O-ring

Commonly used O-ring dimensional tolerances are shown in the table below. If the tolerances are not specified, please consult our technicians for details.

Mobile:+86-13715124957

Email: [email protected]

Whatsapp: +86-13715124957