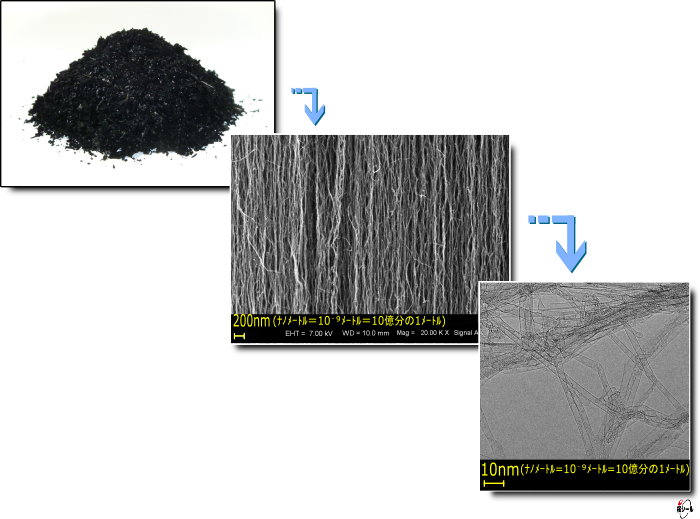

Fluoro-Power FFSG (Fluoro-Power FFSG / FP-FFSG) is a rubber material for O-rings with heat resistance, which is the highest in the world at 370 ℃ class . Various FFKM (perflo) materials, which are considered to be synonymous with high-performance fluororubber , are the flagship of the Fluoro-Power® series due to their excellent chemical resistance as well as heat resistance. It is an advanced polymer compoundthat bears the burden of. Is their raw materials " perfluoroelastomer ( FFKM) to" Nippon Zeon tip material in cooperation with "SGCNT (see Super Growth single-walled Carbon Nanotube = SWNTs / or below supergrowth Method)" It is this Fluoropower FF SG that has succeeded in blending. The encounter of the art, which has played a vertex to as a choice in a high temperature range fluoroalkyl power FFS and fluoroalkyl power FFSW grade refractory grade surpassing the birth, we Ainari and the limit value of the rubber material is increased updated rice field.

| About "SGCNT" from Japan |

| CNT is a kind of allotrope made of carbon, "Carbon Nanotube". Nanomaterials (materials with a particle size of 100 nm or less. 1 nm = 1 nanometer is 10-9 meters, that is, one billionth of a meter), which is considered to be the next-generation carbon material . It is classified into carbon nanotubes (Single-Walled Carbon Nanotube) and MWCNTs (multi-Walled Carbon Nanotubes). The "CNT" of "SGCNT" used in Fluoropower FFSG is SWCNT. SWCNTs have the characteristics of high thermal and electrical conductivity and high strength, and they play an important role in supporting the outstanding heat resistance of Fluoropower FFSG. "SG" in "SGCNT" is a CVD method developed by AIST (National Institute of Advanced Industrial Science and Technology) based on the results of the NEDO (New Energy and Industrial Technology Development Organization) project. It represents one of the (methods of thermally decomposing nanoparticles of catalyst metal and hydrocarbons to obtain CNTs), "a Super Growth method". Although CNT (SWCNT) has rare properties, it is also a material that is difficult to exceed the range of applications for academic research because it requires a large amount of cost for synthesis. The super growth method is what brought the cost closer to a practical level. This epoch-making synthesis technology dramatically extends the life of the catalyst in the synthetic atmosphere by adding a very small amount of water, which makes it possible to produce a large amount of CNT (SWCNT) with 3,000 times the time efficiency of the conventional one. I did. However, SGCNT is still expensive to use as a compounding material for rubber products and is a rubber compound.In the manufacturing process of, there are still many problems such as the need for special technology to uniformly disperse in polymers such as perfluoroelastomer (FFKM). However, I strongly hope that SGCNT and Fluoropower FFSG, spun by Japanese science and technology, will be able to illuminate a wide range of industries and research fields around the world beyond Japan and contribute widely. We are doing it. |

|

* We can manufacture products with various shapes other than O-rings, so please feel free to contact us.

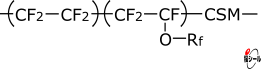

Chemical structure

| 4 Ethylene fluoride / perfluoroalkyl ether copolymer. Since all of the main chains are fluorine bonds (CF) and there are no hydrocarbon bonds (CH), they have extremely excellent chemical resistance and heat resistance. Since the structure is almost fluoride as a whole, it is difficult to crosslink , so CSM is added as an auxiliary leg. |  |

| CSM: Cure Site Monomer |

Related laws and regulations

The content of 10 substances under the RoHS Directive (Pb, Cd, Hg, Cr6 +, PBB, PBDE, DEHP, BBP, DBP, DIBP) is below the threshold.

We do not intentionally add substances subject to REACH regulation.

We do not intentionally add TSCA PBT5 substances (DecaBDE, 2,4,6TTBP, PIP (3: 1), HCBD, PCTP).

Many of the high-performance rubber materials listed by manufacturers such as Fluoro- Power® and Kalrez®can be used interchangeably, but they are given special performance for specific purposes. Some of them are included. When handling it as an equivalent product, carefully check the conditions of use .

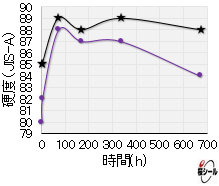

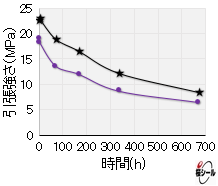

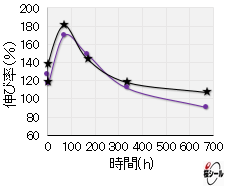

Fluoropower FFSG and high temperature x long time (300 ° C x 670 hours) heat resistant aging test

We conducted a heat-resistant aging test under special conditions (300 ° C x maximum 670 hours) for the top two grades of heat-resistant FFKM (Fluoropower FFSG and Fluoropower FFSW ) . The data is as follows.

| Transition of hardness change | Transition of changes in tensile strength | Changes in growth |

|  |  |

| ||

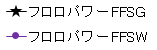

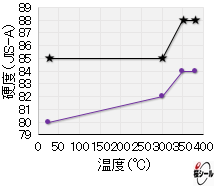

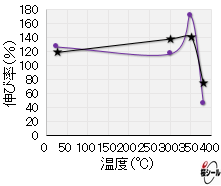

Fluoropower FFSG and temperature-specific ( 25 to 380 ° C) heat-resistant aging test

The data of the heat-resistant aging test (by temperature x 2 hours) conducted on the top two grades of heat-resistant FFKM (Fluoropower FFSG and Fluoropower FFSW ) are as follows.

| Transition of hardness change | Transition of changes in tensile strength | Changes in growth |

|  |  |

| ||

Physical characteristics of Fluoropower FFSG

| Test type | item | Fluoropower FFSG (measured value) |

| Normal physical characteristics test | Hardness (JIS A) | 85 |

| Tensile strength (MPa) | 22.7 | |

| Growth rate(%) | 119 | |

| 100% tensile stress (MPa) | 19.7 | |

| Heat resistant aging test | Test condition | 300 ℃ x 70 hours |

| Change in hardness | +4 | |

| Tensile strength change rate (%) | -16 | |

| Growth rate of change (%) | +52 | |

| Compression permanent strain test | Test condition | 200 ℃ x 70 hours |

| Compression permanent distortion rate (%) | 34 |

Operating temperature limit

The recommended value is 0 to 370 ° C. However, continuous use in the maximum temperature range tends to cause damage due to thermosetting, shortening the service life. Also, in the lowest temperature range , the rubber elasticity deteriorates, so the sealing performance deteriorates . be careful.

Pressure characteristics

The recommended maximum pressure is 10MPa. However, the values will vary depending on the conditions. In addition, the pressure resistance is a combination of the backup ring can be improved by.

chemical resistance

Extremely excellent. It is resistant to all chemicals and has outstanding performance among various rubber materials. Please refer to the table below for a list of durability against more liquids and gases in terms of chemical resistance (compatibility between contact fluid and material) of O-rings .

| Drug name | Resistance | Drug name | Resistance |

| Acetaldehyde | ◎ | Dimethylacetamide | ◎ |

| acetone | ◎ | Diethyl ether | ◎ |

| Aniline | ◎ | heavy oil | ◎ |

| Ammonia water | ◎ | thinner | ◎ |

| IPA | ◎ | Spindle oil | ◎ |

| ethanol | ◎ | 100 ℃ steam | ◎ |

| ethylene glycol | ◎ | Tetrachlorethylene | 〇 |

| Ethylenediamine | ◎ | Tetrahydrofuran | ◎ |

| N-Methyl-2-pyrrolidone | ◎ | kerosene | ◎ |

| Emulsion hydraulic oil | ◎ | Trichlorethylene | 〇 |

| hydrochloric acid | ◎ | toluene | ◎ |

| Engine oil | ◎ | Animal oil | ◎ |

| aqua regia | ◎ | Butyl acetate | ◎ |

| Hydrogen peroxide solution | ◎ | Hydrofluoric acid | ◎ |

| Potassium hydroxide | ◎ | Freon R134a | × |

| caustic soda | ◎ | Inactive fluorine oil | × |

| gasoline | ◎ | Brake fluid | ◎ |

| Cup grease | ◎ | Hexane | ◎ |

| Gear oil | ◎ | benzene | ◎ |

| Xylene | ◎ | formalin | ◎ |

| Light oil | ◎ | Machine oil | ◎ |

| Chloroform | 〇 | water | ◎ |

| Kerosene | ◎ | Water-based cutting oil | ◎ |

| Acetic acid | ◎ | methanol | ◎ |

| Ethyl acetate | ◎ | MEK | ◎ |

| nitric acid | ◎ | Methyl isobutyl ketone | ◎ |

| Vegetable oil | ◎ | Monoethanolamine | ◎ |

| Sodium hypochlorite | ◎ | lacquer | ◎ |

| Dioxane | ◎ | Phosphoric acid ester-based hydraulic oil | ◎ |

| Carbon tetrachloride | 〇 | Sulfuric acid | ◎ |

| Dichloromethane | ◎ | Lithium grease | ◎ |

| Silicone grease | ◎ | Mineral oil-based refrigerating machine oil | ◎ |

◎: Can be used 〇: There is some influence △: Not recommended X: Cannot be used

Note) The above is reference data. Whether it can be used or not depends on the temperature, pressure, and other conditions.

About the use of Fluoropower FFSG (heat resistant FFKM / special grade)

Main usage points

Sealed parts of high temperature cylinders, pistons and rods

Sealing material for high temperature steam boilers

Chemical pump housing and connections

Chemical valves, high temperature valve stems and connections

Sealing material for high temperature vacuum equipment

Sealing material for high temperature fittings

Sealing material for mechanical seals

Sealing material for chemical plant equipment

Sealing material for chemical containers

CVD, diffusion process gate valve

CVD, diffusion process door valve

CVD, diffusion process L-shaped (angle) valve

CVD, diffusion process exhaust fittings

CVD, diffusion process peripherals

CVD, diffusion process chamber lid

Handling precautions

Although it is a material that has excellent weather resistance and is not easily affected by light or heat, store it in a cool and dark place with low humidity just in case.

Please save it in a state where no load is applied. Deformation and cracking are likely to occur if stored in an stretched or compressed state.

Use above the recommended temperature and pressure will cause rapid deterioration. be careful.

Be careful not to come in contact with unsuitable fluids.

Mobile:+86-13715124957

Email: [email protected]

Whatsapp: +86-13715124957